The SM39PWB-CY differential pressure transmitter is used to measure the liquid level, density, pressure, and flow rate of liquid, gas or steam, and then convert it into 4 mA to 20 mADC HART current signal output. It can also communicate with HART handheld terminal for parameter setting, process monitoring, etc.

Differential pressure sensor standard specifications

(Adjust range on standard zero, stainless steel 316L diaphragm, filling liquid is silicone oil)

Differential pressure sensor performance requirement

Reference accuracy of scalrange (including linearity, regression, and repeatability from zero):

± 0.075% If TD> 10 (TD= maximum range / adjusted range) is: ± (0.0075 TD)%

The square root output accuracy is 1.5 times of the above linear reference accuracy. Environmental temperature impact

Over the scope of influence

±0.075%×Span

Static pressure effect

| Quota code | influence quantity |

| UM | ±(0.5%Span)/4MPa |

| B | ±(0.3%Span)/16MPa |

| F /G /H/I/J | ±(0.1%Span)/16MPa |

Overpressure effect

| Quota code | influence quantity |

| UM | ±0.5%×Span/4MPa |

| B /C/D/E | ±0.2%×Span/16MPa |

| F /G /H/I/J | ±0.1%×Span/16MPa |

long term stability

| Quota code | influence quantity | |

| UM | ±0.5%×Span/1 | year |

| B | ±0.2%×Span/1 | year |

| F /G /H/I/J | ±0.1%×Span/1 | year |

Power impact

± 0.001% / 10V (12 to 42 VDC), negligible.

Differential pressure sensor functional specification

Range and range

| Range / range | kPa | |

| UM | range | 0~1 |

| scope | -3000~3000 | |

| B | range | 1~100 |

| scope | -16000~16000 | |

| C | range | 100~500 |

| scope | -16000~16000 | |

| E | range | 500~3000 |

| scope | -16000~16000 | |

| E | range | 3000~4000 |

| scope | -16000~16000 | |

| F | range | 4000~10000 |

| scope | -16000~16000 | |

| G | range | 1~100 |

| scope | 16000~30000 | |

| E | range | 100~500 |

| scope | 16000~30000 | |

| EU | range | 500~3000 |

| scope | 16000~30000 | |

| Eu | range | 3000~4000 |

| scope | 16000~30000 | |

Quantity limit

In the upper and lower limits of the range, can be adjusted.

It is recommended to choose a range code as low as possible to optimize the performance characteristics. Zero point setting

The zero and range can be adjusted to any value within the measurement range in the table, as long as the calibration range minimum range

Installation location impact

The change of the installation position in the parallel direction of the membrane will not cause zero drift effect. If the installation position and the one direction of the membrane change more than 90°, the zero position in the range of <0.4 kPa will occur, which can be adjusted by adjustment. There is no quantitative impact.

saída

Second-line system, 4 mA ~ 20 mADC, optional HART output digital communication, optional linear or square root output. Output signal limit: Imin=3.9mA,Imax=20.5mA

response time

The damping constant of the amplifier component is 0.1s; the sensor time constant is 0.1s~1.6s, depending on the range and the range ratio. The additional adjustable time constant is: 0.1s~60s. The effect on the nonlinear output (e. g., the square root function) depends on that function and can be calculated accordingly.

preheating time

<15s

ambient temperature

-40℃~85℃

-20℃ ~65℃ with liquid crystal display and fluorine rubber sealing ring

-50℃ ~85℃; with liquid crystal display: -40℃ ~85℃ working pressure

The rated working pressure is divided into: 16MPa, 25MPa and 40MPa three gear static pressure limit

From 3.5kPa absolute pressure to rated pressure, the protection pressure can be 1.5 times the rated pressure and added to both sides of the transmitter. One-directional overload limit:

Electromagnetic compatibility (EMC)

See EMcompatibility schedule on the following page

Differential pressure sensor install

Power supply and load conditions

The power supply voltage is 24V, R (Us-12V) / Ima xkΩ among Ima x=23 m A

Maximum power supply voltage: 42VDC

Minimum power supply voltage: 12VDC, 15VDC (backlit liquid crystal display) digital communication load range: 250 Ω ~600 Ω

Conexão elétrica

M201.5 cable seal buckle, the wiring terminal is suitable for 0.5m m2~2.5m m2The wire.procedure linkage

The two sides of the process connection flange have NPT 1 / 4 and UNF 7 / 16 ″ internal threads.

Differential pressure sensor Physical specifications

material quality

Measurement membrane box: stainless steel 316L

Membrane: stainless steel 316L, Harbin alloy C process flange: stainless steel 304

Nuts and bolts: stainless steel (A4) filling fluid: silicone oil

Seal ring:, nitrile rubber (NBR), fluorine rubber (FKM), polytetrafluoroethylene (PT F E) transmitter shell: aluminum alloy material, exterior spray epoxy resin

Housing sealing ring: Nitrile rubber (NBR) nameplate:, Stainless steel 304

weight: 3.3kg (without: LCD display, mounting bracket, process connection)

Housing protection class IP67

The EMC schedule

| order number | test item | basic criterion | test condition | Performance level |

| 1 | Radiation interference (enclosure) | GB / T 9254-2008 Table 5 | 30MHz~1000MHz | qualified |

| 2 | conducted interference(DC power supply port) | GB / T 9254-2008 Table 1 | 0.15MHz~30MHz | qualified |

| 3 | Electrostatic discharge (ESD) immunity | GB/T 17626.2-2006 | 4kV (contact point)8kV (air) | B |

| 4 | RF electromagnetic field immunity | GB/T 17626.3-2006 | 10V/m(80MHz~1GHz) | UM |

| 5 | Power-frequency magnetic field immunity | GB/T 17626.8-2006 | 30A/m | UM |

| 6 | Electric fast transient pulse group immunity | GB/T 17626.4-2008 | 2kV(5/50ns,5kHz) | B |

Note 1: A Performance grade description: normal within the limit of technical specification.

Note 2: B Performance rating description: During the test, the function or performance is temporarily reduced or lost, but it can be restored by itself, and the actual health, storage and data do not change.

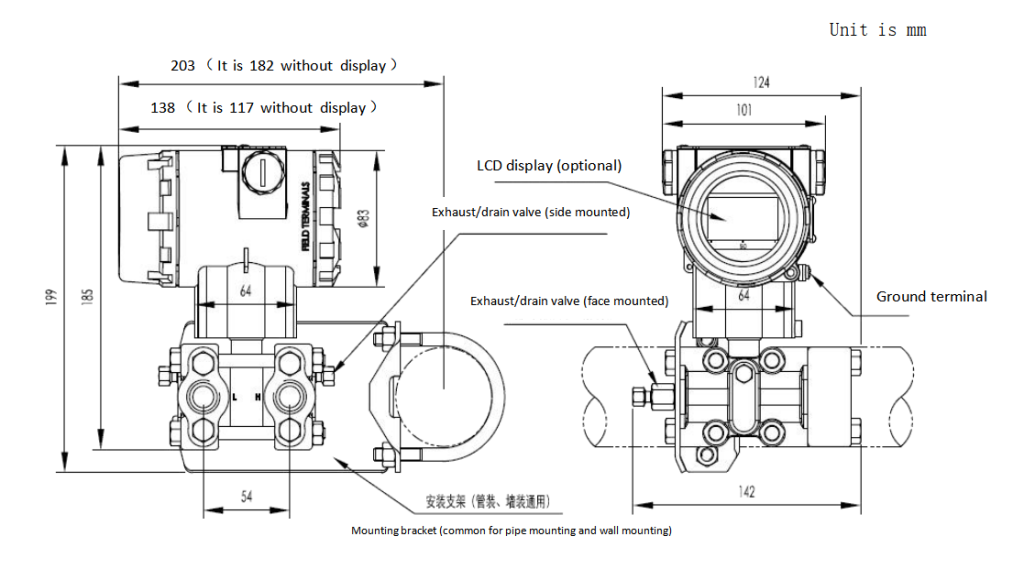

Outline dimension

Entre em contato conosco!

Produtos relacionados

Produtos relacionadosparceiro

parceiro

download

download